Continuous online monitoring of high-pressure homogenization processes

Online monitoring of the particle size distribution (PSD) of emulsions for intravenous application of pharmaceuticals,

parenteral nutrition during homogenization to ensure formulation stability.

Challenge

The particle size distribution of parenteral emulsions is a critical quality attribute (CQA).

Christoph Koeth and his colleagues tested a number of sensor systems for online monitoring of their emulsions. A chance meeting with Chris Hill and Gerhard Prossliner from BRAVE Analytics led to the joint collaboration and development of the BRAVE B-Curious PAT sensor.

The challenges are:

- The time lag inherent with laboratory measurements leads to inefficient production processes.

- Offline measurements are time-consuming and require qualified personnel.

- Current offline methods provide results too late for process optimization.

- Current measurements do not capture all fluctuations and anomalies.

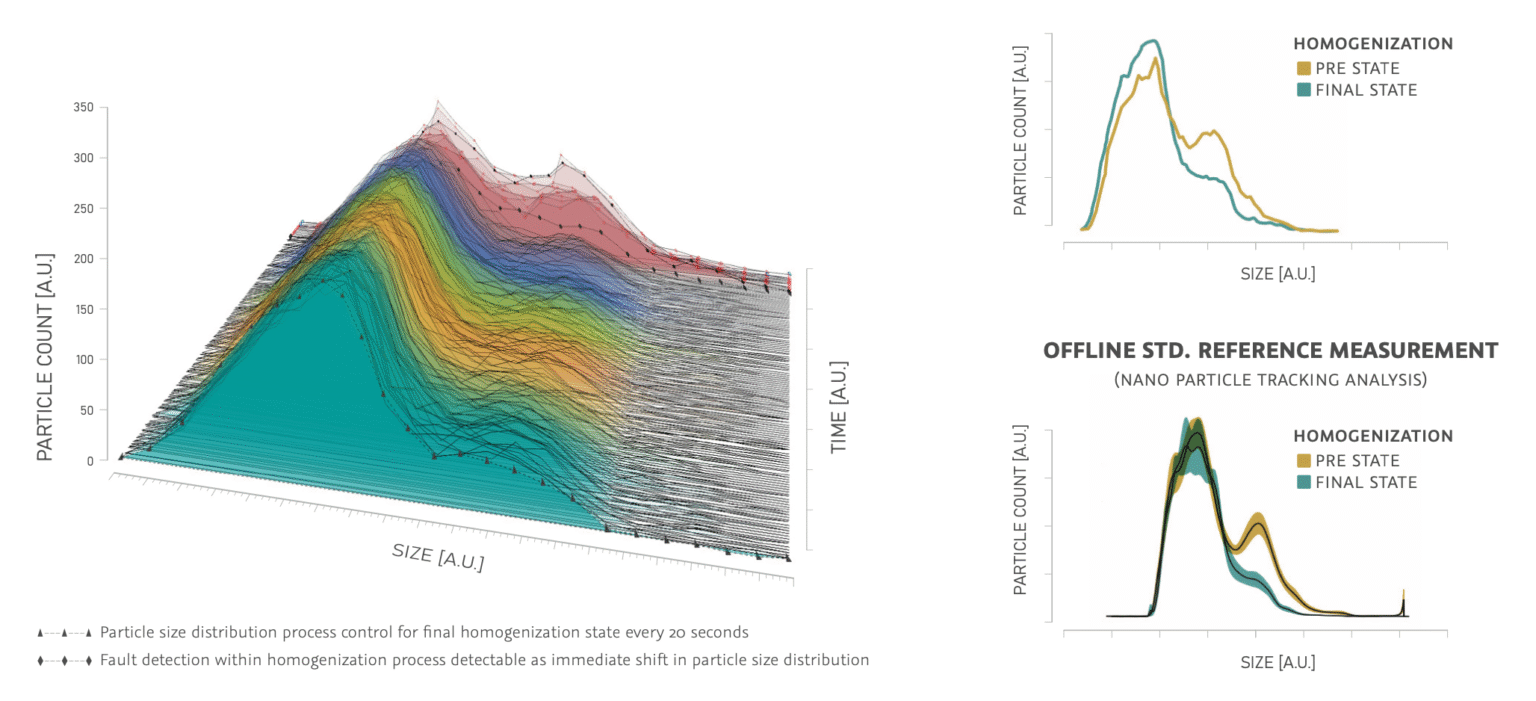

Figure 1: OF2i® time-resolved online characterization as number-based size distributions versus nanoparticle tracking analysis of different processing steps in looped emulsion production. Timestep 10: fault detected within homogenization. © BRAVE Analytics & Marko Šimić

Application highlights

The BRAVE B-Curious online unit (including a continuous and automated online sample preparation unit) was installed in a four-stage homogenization pilot plant.

After the first step, the particle size is reduced from 3 µm to approx. 0.3 µm. The process analyzer continuously monitors the PSD distribution and automatically evaluates data such as D-values to assess the efficiency of the first homogenization step.

- The values are sent to the LIMS every 20 seconds.

- A better understanding of the homogenization process leads to more efficient production and huge savings in product waste.

The analysis setup used in this case

BRAVE B-Curious PAT sensor for determining the particle size distributions of polydisperse systems with single-particle sensitivity in-flow directly from the production line.

Measures the number-based, hydrodyamic particle size distribution.

Detection range

50 nm* to 3 µm* (*sample-dependent, expected range)

Concentration range

min. 104 particles/ml (optimal: ≤1010 particles/ml)

Minimum required bypass flow

plant-dependent, custom-tailored solution for each case